Palletizer with cobot technology

Safety first

We exceed the standards of ISO 10218:2025 with innovative collaborative solutions. It's safety made Friendustrial™ —where human-robot interaction is seamless, productive, and secure.

Plug and play

TOMA™ is an out-of-the-box solution. Once it arrives on your floor, it is easy to integrate with your existing line and will be up and running in minutes.

Easy to operate

Everyone can operate our HMI, powered by MOVN™. Enter your case dimensions, select your pallet pattern, press start, and you’re ready to go.

PAL Series Palletizer

Find out more about the TOMA™ PAL-0830’s technical specifications

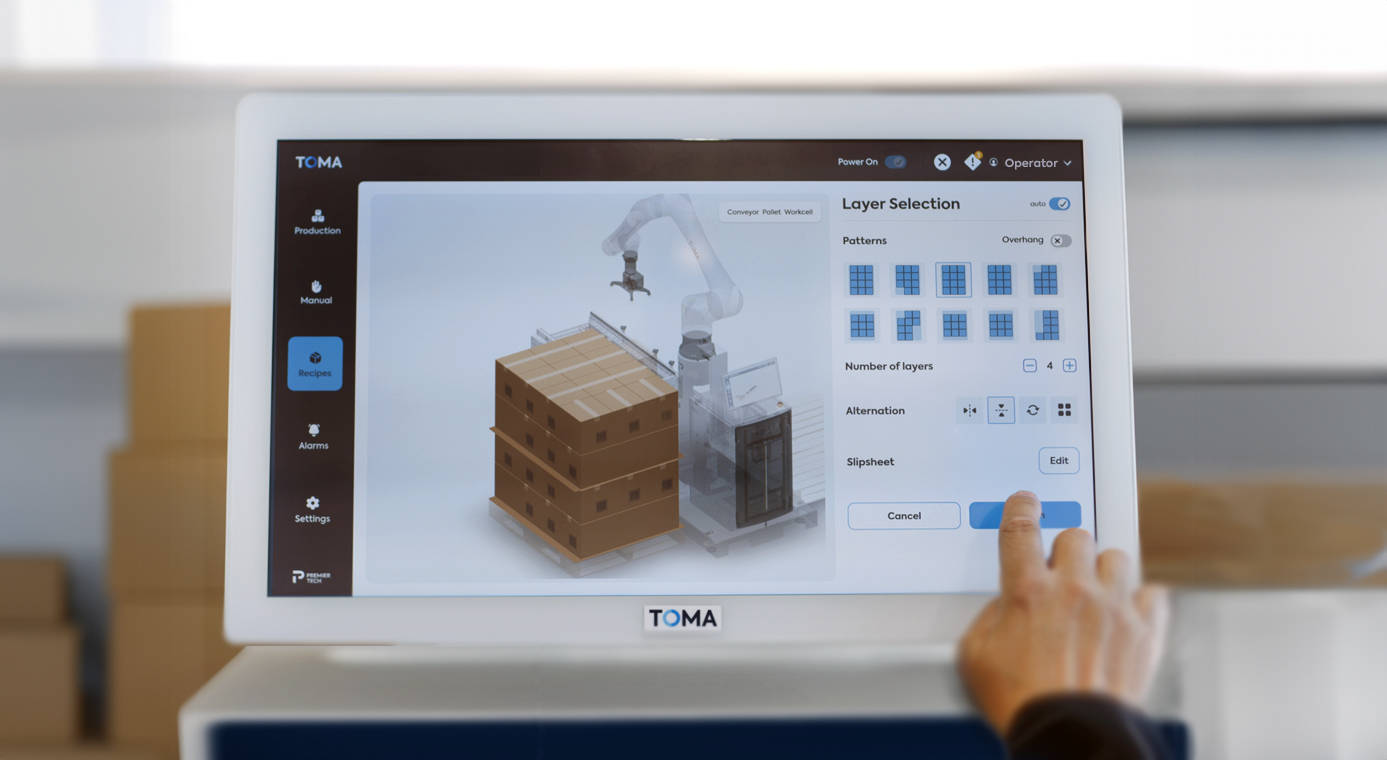

HMI powered by MOVN™

Our team has developed the most advanced and user-friendly HMI on the market, our proprietary software, MOVN™. It is designed to empower you throughout your day-to-day operations. This is an HMI touchscreen so intuitive and streamlined, anyone can get palletizing in minutes. Enter your product’s specs and label orientation, pick a pallet pattern, press start, and get MOVN™.

Friendustrial™ safety

At TOMA™, we use ISO 10218:2025 as a foundation, but we go beyond the standard. Our collaborative solutions are built around the principle of safety made Friendustrial™: making safety an intuitive, seamless part of working alongside automation. The standard helps guide our best practices from thorough risk assessments to smart design to ensure the safety and validation of shared workspaces so people and technology can operate together with confidence, efficiency, and trust.

Performant and robust cobot

The integrated FANUC CRX-30iA cobot arm handles payloads up to 66 lb (30 kg). Our packaging experts put ingenuity to work to reach up to eight picks per minute in collaborative mode, which is above average for a CRX-30iA. We’ve unlocked the potential for you to benefit from the most reliable cobot on the market, without sacrificing speed. That’s the TOMA™ difference.

Neat pallets every time

Maximize your operations by using the integrated TOMA™ conveyor, allowing optimal repeatability and precision. You can even palletize from up to two 4-foot TOMA™ conveyors at the same time. Get everything precisely in place quickly using the coupling brackets on the conveyors and the palletizer base. Get Premier Tech’s quality loads, every time.

Empowering connection

Assess equipment performance and make adjustments quickly with integrated Necton™ technology. Get actionable insights and make real-time adjustments to optimize the efficiency of your operations.

Get MOVN™, configure TOMA™

1.Answer a few questions

2.Click to select options

3.See TOMA MOVN™

TOMA™ is changing the game for palletizing operations in all industries

See how the TOMA™ palletizer helped a not-for-profit company palletize 2,000 to 3,000 boxes each day, allowing them to open a second production line.

Groupe TAQ

Discover how Boulangerie Dumas stayed competitive in a highly mechanized market by boosting productivity with the TOMA™ palletizer.

Boulangerie Dumas

Frequently asked questions

No, everything is assembled and tested before shipping. This means, you don't have to waste time with complicated assembly instructions and missing components. You simply need to connect your gripper and conveyor to get MOVN™.

Yes, you can create custom routines using the provided FANUC Teach Pendant tablet. You can then save the created routine to your HMI to use it later, for example, in a different recipe, without having to pull the tablet out again.

No, the base is solid and stable enough to not require anchoring down. Anchoring brackets are included nonetheless.