Groupe TAQ

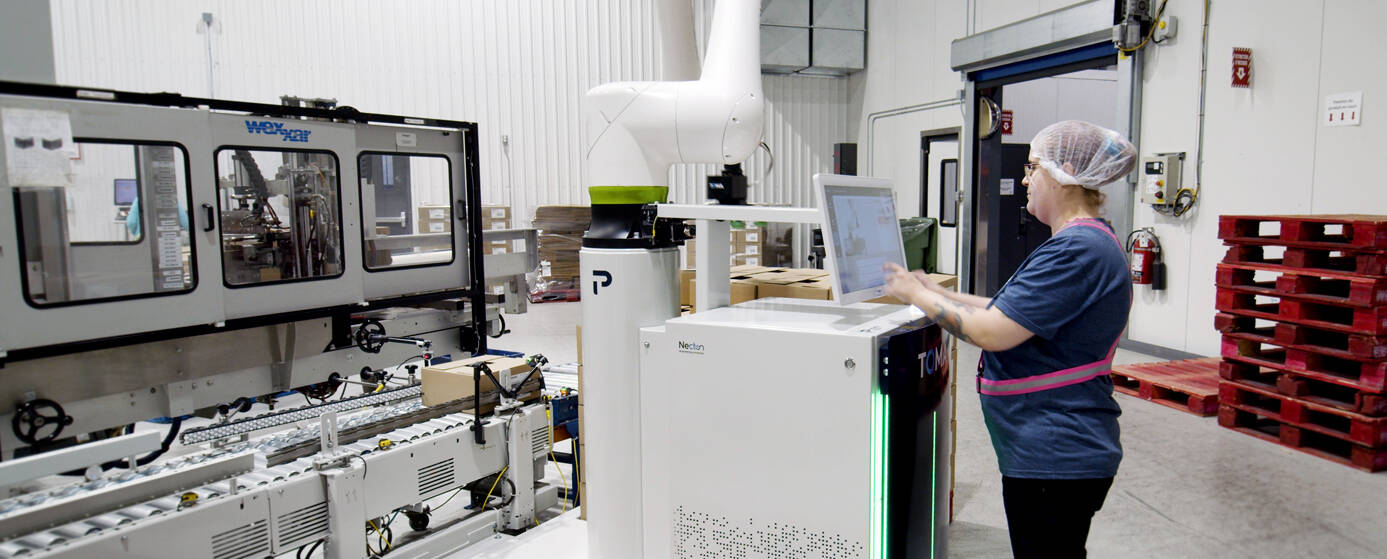

In the heart of Quebec lies Groupe TAQ, a social enterprise committed to creating an inclusive work environment for people with disabilities. To respond to a recent project, they investigated using collaborative robots in their manufacturing space and decided to adopt a TOMA™ palletizer.

The power of human-robot collaboration

For a recent food industry project, Groupe TAQ needed to palletize 2,000 to 3,000 boxes daily, requiring two to three workers on a single production line. To improve this workflow, the TOMA™ PAL-0830 palletizer, with its user-friendly design and intuitive interface, emerged as the perfect fit. Its standout feature was its ability to handle repetitive tasks safely alongside human workers, reducing the risk of injury from repetitive motion. By automating this palletizing task, TOMA™ has not only increased safety but increased overall throughput.

“A nice thing about TOMA™ is that it’s hyper flexible. You can just take a trucklift, move it to another place, and move the conveyor with it. It all works together, so it’s the same position for everything.”

— Pascal Gagne, Director of Operations

Embracing automated workplaces

Groupe TAQ’s experience with the TOMA™ Palletizer demonstrates the tremendous potential of human-robot collaboration in manufacturing. By integrating TOMA™ into their packaging operations, Groupe TAQ fostered a safer, more efficient, and inclusive environment for their team members. This project’s success highlights the value of collaborative automation solutions that are efficient, accessible, and easy to use.

Highlights

Flexibility

TOMA™ equipment can seamlessly switch from one job to another, adapting to dynamic needs.

Greater job satisfaction

While TOMA™ takes care of the heavy lifting, human workers are empowered to explore more dynamic roles.

100% intuitive

TOMA™ makes automation accessible. Even users at a beginner level can set up and run the programs.

Featured equipment

Is TOMA™ the right solution for you?

TOMA™ makes automated solutions Friendustrial™, bringing the power of automation to everyone in an accessible way. Take a look at our offerings to see whether TOMA™ is the right fit for you.