Why should you consider 3D printing as a manufacturer?

Could 2025 be the year you choose to take your business in a new direction? If you’re considering your options and think that exploring a new technology might be what you need, we’re here to help. In this series, we’re looking at the top automation trends in manufacturing of 2025, and next up is a closer look at the intriguing potential of 3D printing in the manufacturing industry.

As a small business owner, you know the benefits of taking calculated risks with the potential for a big payoff. If you’re staying on top of the latest manufacturing automation trends in 2025, you’ll be aware of the power of 3D printing. A flexible, cost-effective solution, 3D printing has the potential to drive efficiency and facilitate innovation. Here’s how 3D printing is used in manufacturing and why it could be the strategic leap you’re looking for this year.

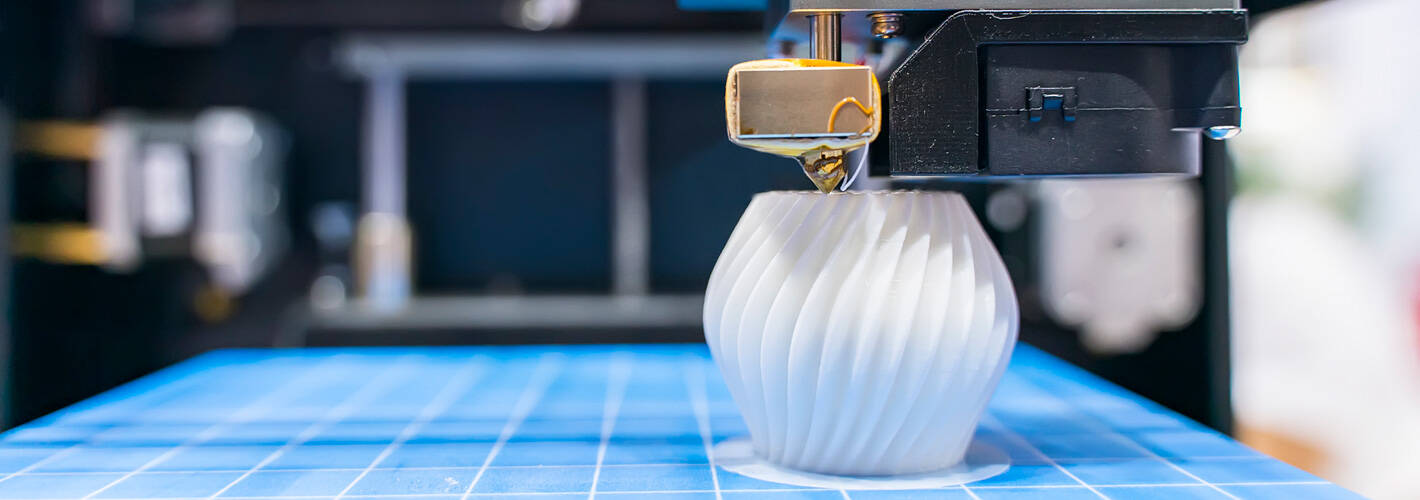

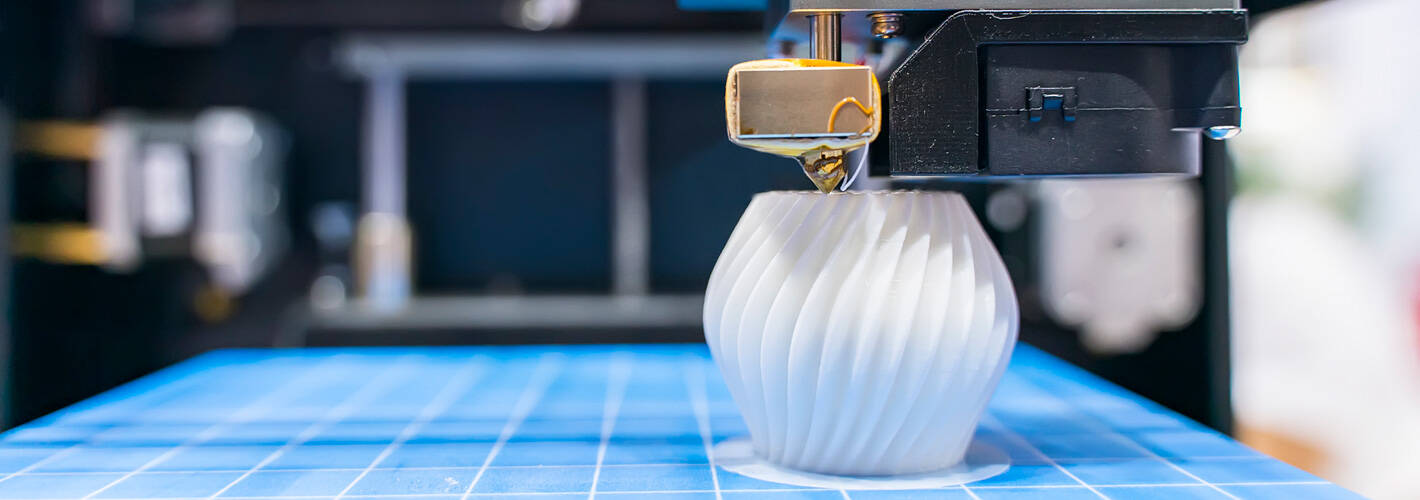

How 3D printing works: A basic introduction

3D printing, or additive manufacturing, is a process where a physical object is created layer by layer from a digital design. Unlike conventional manufacturing techniques, which involve cutting, molding, or assembling parts, 3D printing builds up material (like plastic, metal, or resin) to form the final product. Here's a basic breakdown of the steps involved:

- Create a digital design: First, you design your imagined product using 3D modeling software (Tinkercad is a free, easy-to-use app, while Fusion 360 is on the complex end). If you don’t have the skills to design it yourself, there are many pre-made models available online. You can also choose to hire a designer instead.

- Convert to STL format: Once your design is ready, it needs to be converted into something called an STL (stereolithography) file. This is the only format that 3D printers can understand.

- Printing process: The 3D printer reads the STL file and starts printing the object layer by layer, typically from the bottom up. It can use materials like plastic filament, resin, or metal powder, depending on the type of printer.

- Finishing: After the object is printed, it may require some post-processing work. For example, it may need cleaning, curing, or painting, depending on the material used.

Amazingly, with 3D printing, if you can imagine an object you need, you can create it and have it in hand in as little as an hour or two!

Is 3D printing the same as additive manufacturing?

Yes! The two terms describe the same process, with additive manufacturing referring to how an object is built layer by layer, gradually adding material until the final product is complete.

3 advantages of 3D printing for the manufacturing industry

Your mind is likely buzzing with the potential of 3D printing in manufacturing automation processes. Imagine being able to test an idea for a product in your own warehouse within minutes! To help spark even more ideas, here’s a quick survey of some of the key benefits.

1. Low upfront investment

Unlike traditional manufacturing methods that often require expensive molds and machinery, 3D printing reduces costs by making parts directly from a digital design. Desktop 3D printers can start as low as $300 for basic models, with industrial-grade machines costing anywhere between $2,000 to $50,000 depending on your needs.

2. Rapid prototyping and customization

One of the standout benefits of 3D printing is rapid prototyping. You can quickly design, test, and iterate products without the need for expensive molds or tools. Additionally, it’s easier to customize products or produce low-volume, highly specialized items—perfect for niche markets or unique customer needs.

3. Material versatility and sustainability

Modern 3D printers support a wide range of materials, which makes them versatile for many different industries. Plus, many businesses appreciate the sustainability factor: 3D printing generates less waste than traditional methods and can even use recycled materials.

What to consider before getting started

Learning curve: While 3D printing technology has become more accessible, there is still a learning curve. Familiarizing yourself with design software is essential—or being willing to offload this task to a designer.

Production speed: While 3D printing is great for prototyping, large-scale production will take longer compared to traditional methods. Evaluate your timeline and decide what fits your production needs.

Cost of materials: The price of materials can vary widely based on the type you choose, so make sure to factor that into your budget.

3D printing and manufacturing: Your strategic next step

3D printing offers small businesses the ability to innovate, customize, and produce on-demand without the burden of high upfront costs. While it’s not a one-size-fits-all solution, it's certainly an option worth exploring if you want to push the boundaries of what's possible in manufacturing.

Are you ready to embrace the future?